Article from the Jasper Journal 4th Quarter 2018

Written by: Melissa Winebarger

Whew, we did it!

This is the thought I have as we wrap up 2018. Our Jasper Ventures family has accomplished more this year than ever before. This has only been possible because everyone took their position seriously, worked as a team, and encouraged one another so that we were able to reach big, audacious goals.

The Bible says, “In their hearts humans plan their course, but the Lord establishes their steps.” (Proverbs 16:9) We knew from the beginning that 2018 would be busy and maybe crazy, but we planned for what we could and allowed the Lord to establish our steps. We did not always get it right, but we course-corrected and moved ahead. We completed more projects and learned from our challenges. And we are looking forward to all 2019 holds – including the challenges.

Jasper Ventures’ mission is to provide customized, cost-effective, full-service solutions in the areas of engineering, design, construction, installation, operations, and leasing for our midstream oil and gas industry. We had our biggest year yet in all areas. Our unique ability to fabricate in-house at our Troup and White Oak facilities allows us to see problems before they arise. Our process engineers are diligent to inspect each plant before it leaves the fabrication facility to ensure every instrument is accurate.

This is not to say we do not incur challenges once the puzzle pieces get to the field. Our Vulcan installation crews, led by Jeremy Cartwright, face many obstacles. With the numerous on-site jobs within the industry as a whole, resources run thin at these remote locations. Rentals, manpower, materials, and lodging are sometimes unavailable or low. We are thankful for our Vulcan leadership and team members who step up to the challenge, working long hours to get the jobs done. We are grateful for their flexibility when obstacles arise and their diligence in meeting expectations and deadlines.

With a record number of completed start-ups this year we have had more construction jobs overlapping at one time than ever before. Our teams in the pipe shops, assembly, paint, and structural have all worked tirelessly to provide timely deliveries. We celebrated one million man hours without a reportable incident earlier in the year thanks to their cautious work.

We knew going into 2018 that more manpower would be necessary to deliver the projects on our roadmap. Little did we know this would lead us to hire 100+ new team members over the course of the year with nearly 20 of those being newly created positions. With this kind of growth, it can be challenging to maintain a culture of unity, but we continue to be reminded of our need for one another in this business and in life.

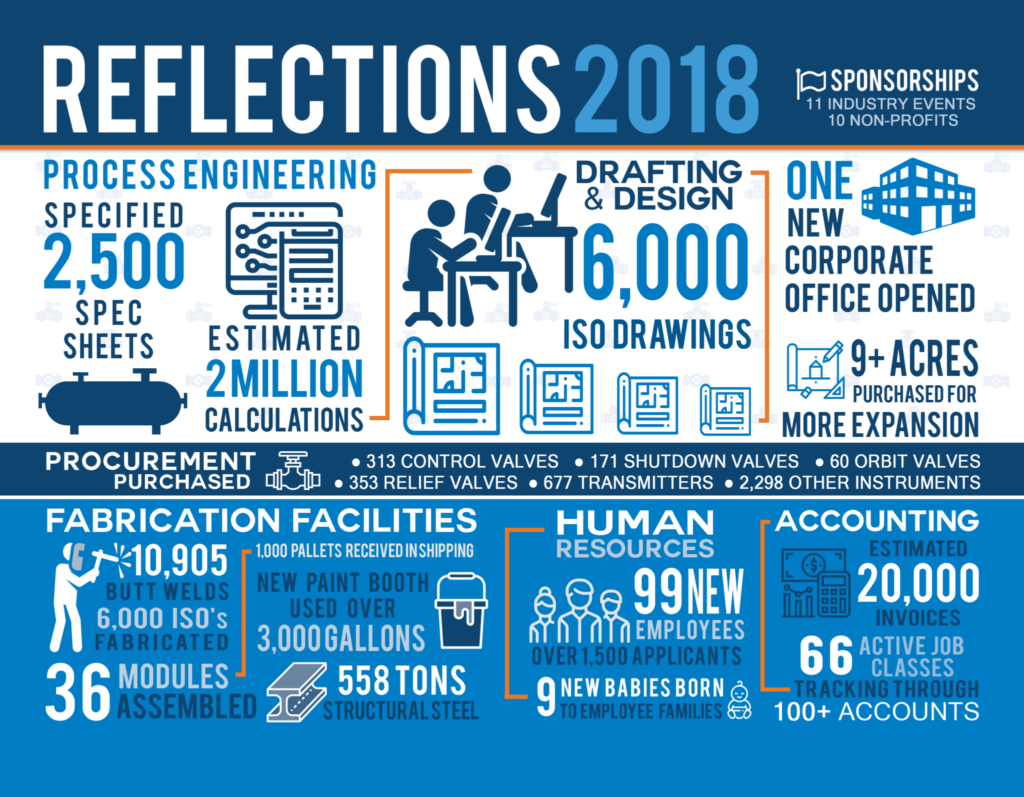

With help from every department, over the last 12 months, Jasper Ventures family of companies accomplished the following:

- Completed installation and start-up of a 200 MMSCFD Cryo Plant in Eddy County, NM, in April

- Completed installation and start-up of a 200 MMSCFD Cryo Plant in Kingfisher County, OK, in May

- Completed installation and start-up of a 120 MMSCFD Cryo Plant in Kingfisher County, OK, in July

- Completed installation and start-up of a 200 MMSCFD Cryo Plant in Reeves County, TX, in October

- Completed installation and start-up of a 300 MMSCFD Booster Compressor Station in Culberson County, TX, in November

- Completing installation and start-up of a 90 GPM Product Treater in Culberson County, TX, by December

- Completing installation and start-up of a 550 GPM Amine Unit and a 42 GPM TEG Unit in Reeves County, TX, in December

- Completing installation and start-up of a 290 GPM Amine Unit in Eddy County, NM, in December

None of this is possible without the work of every department. To every project manager, thank you for caring about the client and not just the job. Thank you process engineers for every calculation you run over and over. We are grateful for every guy and gal on the drafting team whose attitude and heart amaze me. The I&E team are like secret elves; we rarely see them, but their work is impeccable. Our plants would not run without proper instrumentation, thanks I&C gang. We ask a lot of the shops in Troup and White Oak, and they are faithfully committed to every task. We appreciate the skill, talent, and long days they give. We are grateful to the Vulcan field crew who works in all sorts of harsh weather and spend many hours away from their families. We appreciate the Vanguard team who keep Black River running 24 hours a day. And none of this would be possible without the back-office functions providing resources so all the front-line people can do the real work. Thank you all!

Like any growing company, Jasper Ventures incurs challenges, but we continue to pull together, learn from mistakes, and find innovated solutions. As we step in to a new year, I pray you dream big, audacious goals for yourself and believe in the big, audacious goals we have for the Jasper Ventures family.

Download our Reflections 2018 infographic below:

READ THIS ARTICLE AND OTHERS FROM THE LATEST

EDITION OF THE JASPER JOURNAL BELOW:

Please feel free to distribute to friends, family, vendors or anyone you think might enjoy learning more about our company. The direct link for this edition of the journal is: https://indd.adobe.com/view/674ce123-2e6d-470d-a529-c918d63b21f3

For the latest news about Jasper Ventures visit www.jasperventuresinc.com/latest-news-media